1. Product Introduction

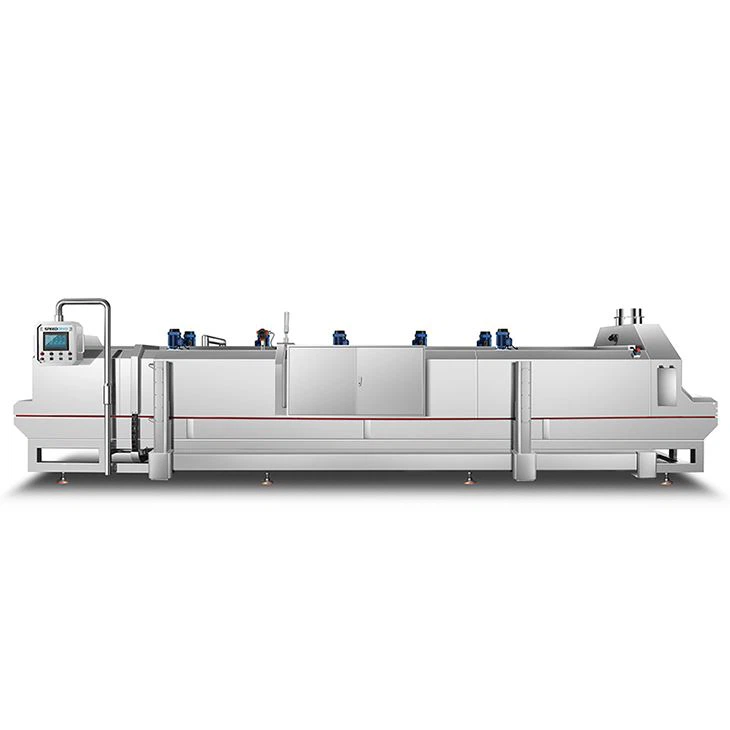

Liquid Nitrogen Industrial Cryogenic Food Freezers

Our leading-edge liquid nitrogen food freezing systems rapidly freeze products to peak quality. Harnessing ultra-low cryogenic temperatures, these industrial food freezers maximize throughput, efficiency, and preservation.

Advanced liquid nitrogen spray technology instantly freezes foods while minimizing damage. Intelligent temperature controls optimize the freezing profile for each product. Automated conveying tunnels facilitate consistent, high-volume processing.

2. Product Parameter

| Model: | JSSD-1112 Liquid Nitrogen Food Freezer | ||

|---|---|---|---|

| Whole Dimensions: | 1106*215*190(cm) | Belt Dimensions: | 1100*120(cm) |

| Entrance Length: | 96(cm) | Exit Length: | 50(cm) |

| Inside Height: | Adjustable 50 ~150mm | Freezing Capacity | 1000 ~ 1200kgs/h |

| Weight: | About 4900 kgs | Voltage: | 380V |

| Material: | SS 304, Stainless Steel | Power: | 11000W |

3. Product Features and Application:

From seafood, meat, and poultry to baked goods, vegetables, and prepared meals, our cryogenic food freezers produce superior frozen results across applications. Maintaining premium quality attributes unlocks higher sales prices and profits.

Choose from a broad range of capacities, dimensions, and configurations to match your needs. CE-certified with high-end components, our liquid nitrogen food freezers deliver rapid, reliable freezing year after year. Let us customize an efficient cryogenic solution to help you gain a competitive advantage.

4. Details Information:

- Simple Assembling Design

- High Tightness for Longer Time Heat Preservation and Energy-saving

- Simple and Rapid Replacement of consumables

5. Product Qualifications:

- CE Certificates

- ISO 9001 Certificates

- Excellent Research and Development Engineer

- Equipment design and production meet international standards- Strict Quality System

- A Good After-sales Service

6. About Us

Guiding Global Frozen Food Innovation for Over 20 Years

As pioneers in cryogenic food freezing, we draw from over two decades of experience and expertise. Our team stays at the leading edge by continuously advancing our equipment technology. We hold numerous patents and have installations worldwide.

By leveraging our technical knowledge and freezing best practices, we can optimize your production. Our specialists collaborate with you to determine the ideal cryogenic food freezer specifications and procedures for your goals. Contact us today to elevate your frozen food quality and efficiency.

7. FAQ

Why choose our liquid nitrogen industrial food freezers?

Compared to traditional mechanical freezing methods, our cryogenic systems offer unparalleled speed, quality, and cost advantages:

-

Freezing times up to 5~20 times faster, with most items fully frozen in minutes rather than hours. This rapid freezing kinetics better preserves flavors, textures, and nutrition.

-

Smaller intracellular ice crystals minimize damage to cellular structures. Slow freezing causes large extracellular crystals that rupture cell walls. Our flash freezing preserves quality.

-

Automated process control and monitoring enable consistent, ideal freezing tailored to each product. Humidity, dwell time, and core temperature are precisely regulated.

-

Lower upfront investment than equivalent mechanical freezing capacity, along with lower operating costs. The cryogenic process has fewer moving parts and downtime.

-

Liquid nitrogen provides more cooling capacity per unit volume versus mechanical refrigerants, allowing greater throughput per square foot.

By leveraging these cryogenic freezing benefits, processors can enhance quality, efficiency, and profits. Let our freezing specialists tailor an advanced industrial food freezing solution to your needs.