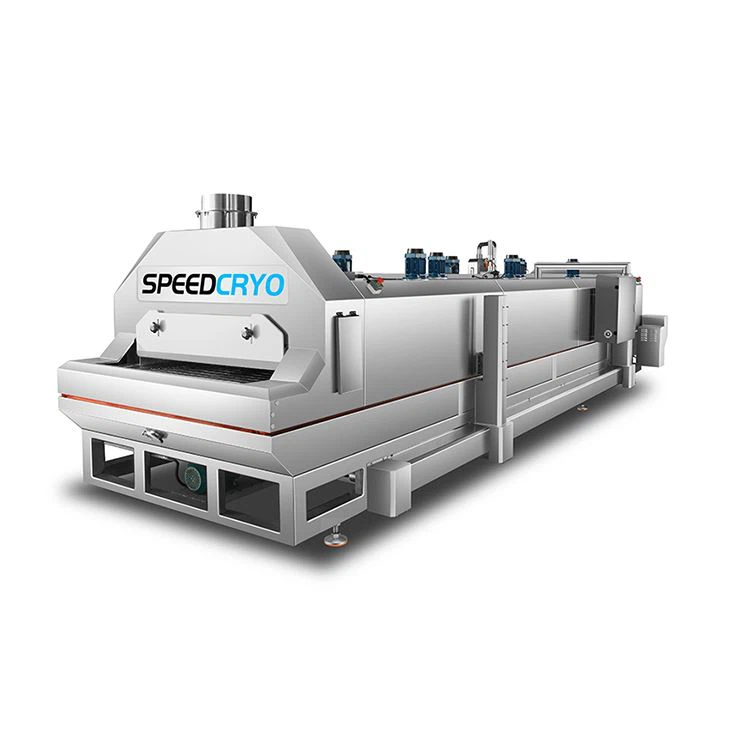

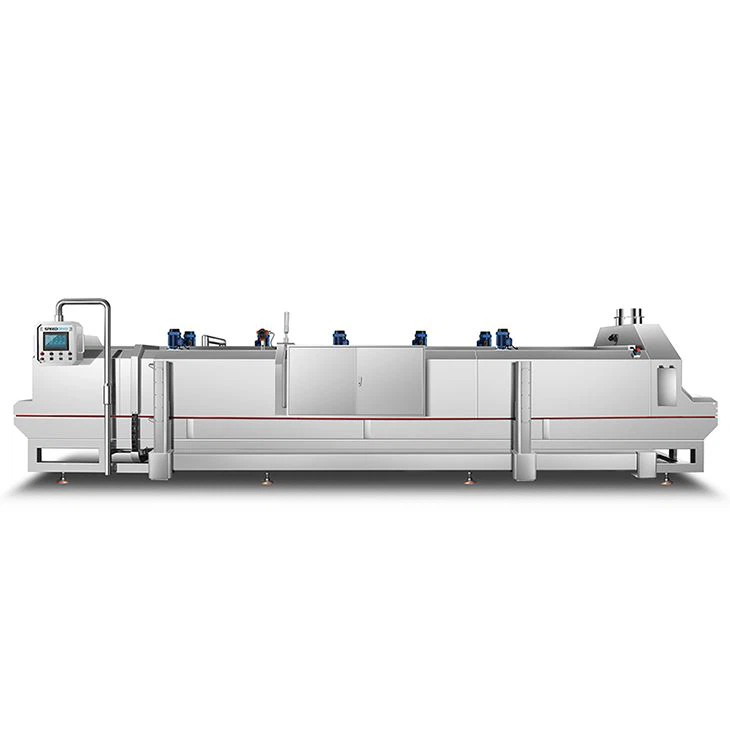

1. Product Introduction

The advanced quick-freezing technology using LN2 as cryogen is adopted by our fast freezing tunnel, can freeze food rapidly and get through growth of ice crystal without damaging cell structure and losing water to preserve original appearance, taste and quality of food.

It is well known that the faster freezing time to make center temperature of food reach -18℃ below, the better food condition could be maintained. Our fast freezing freezer could freeze most of kind of food in 5 ~ 20 minutes, which is recognized by more and more food processing enterprises and consumers

2. Product Parameter

| Model: | JSSD-0912 Liquid Nitrogen Fast Freezing Tunnel | ||

|---|---|---|---|

| Overall Dimensions: | 9.14*2.15*1.90(m) | Conveyor Dimensions: | 9*1.2(m) |

| Inlet Length: | 0.96(m) | Outlet Length: | 0.5(m) |

| Inlet Height: | 50 ~150mm Adjustable | Freezing Capacity | 700 ~ 1000kgs/h |

| Weight: | About 4600 kgs | Voltage: | 380V |

| Material: | Whole Body SUS 304 | Power: | 11KW |

3. Products feature and application:

Liquid nitrogen fast freezing freezer is applicable to various food such as aquatic products, meat and poultry, fruits and vegetables, prepared foods etc.

Take fish processing enterprise for example, fish freezing tunnel could be perfectly integrated with the existing assembly line production equipment and does not require additional purchase of new machines, saving input costs and improving the efficiency of quick freezing, ensuring the safety and high quality of quick-freezing products.

4. Details Information:

- Temperature Precision: ±2℃

- Cooling Rate: ≥20℃/min

- Effective Exhaust Fan

- Reasonable Circulation Fan Designed Saving Energy

- Warning System: Oxygen Concentration Alarm, Liquid Nitrogen Pressure Alarm

5. Product qualifications:

- CE Certificates

- ISO 9001 Management System Certification

- Rich research results and experimental data are used for product development and production

- 100% Quality Control in Production and Inspection

6. Machine Customization Process

In order to meet the needs of different customers, the length and width of fast freezing tunnel can be customized according to customer requirements

- Understand the needs of customers (food types, freezing capacity)

- Analyze the layout of the customer's production workshop

- Determine the model or size of fast freezing freezer

- Internal review the drawings and plans of fast freezer

- Submit the plan, modify the plan according to the opinions from customers

7. FAQ:

Does the liquid nitrogen fast freezer need to defrost regularly? What are the ways to defrost?

a. Air Convection Defrost

Run the circulating fan only, and use the air convection to melt the frost inside the machine.

b. High Pressure Gas Defrost

Use the high-pressure gas of the air pump to blow off the frost in the equipment.

c. Water Mist Defrost

When the temperature inside of equipment rises to 0℃~10℃, spraying by a high-pressure water gun or a water gun with spray function to remove the frost.