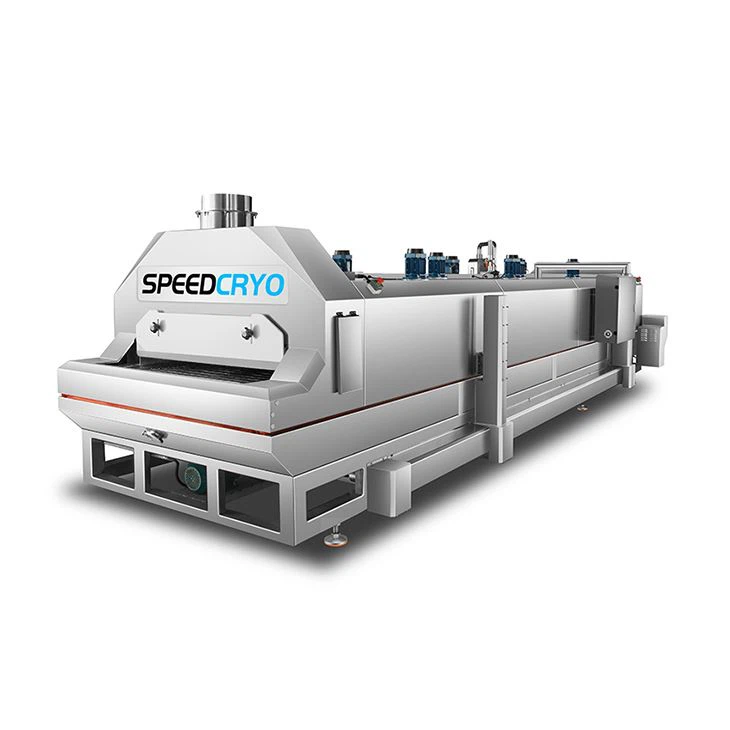

1. Product Introduction

Cryogenic IQF (individually quick frozen) freezers utilizing liquid nitrogen provide unmatched speed, efficiency, and quality for frozen food processors. By instantly freezing products down to ultra-low temperatures, liquid nitrogen IQF systems preserve original nutrition, flavor, texture, and appeal better than conventional methods.

Rather than slow, damaging ice crystallization, cryogenic IQF freezers flash-freeze items near-instantly. Independent freezing tunnels with adjustable temperature profiling expose foods to cryogenic temperatures for precise durations. Automated monitoring of dwell time and product core temperature prevents over-freezing.

Liquid nitrogen IQF freezers freeze products in minutes versus hours for mechanical units. The rapid freezing kinetics maintain small intracellular ice crystals, protecting delicate cellular structures. Chemical and enzymatic degradation is also minimized, retaining color, pigments, and nutrients.

Automated cryogenic IQF systems simplify production. Enclosed freezing protects worker safety. Minimal labor is needed for loading and unloading. A compact footprint saves valuable factory floor space. Liquid nitrogen IQF freezers also integrate seamlessly into existing or new production lines.

The upfront investment pays dividends through higher product quality, increased yields, and production speed. Partner with our cryogenic freezing experts to optimize your IQF capabilities. We can help you leverage leading-edge liquid nitrogen IQF freezers to improve frozen food safety, quality, and profitability.

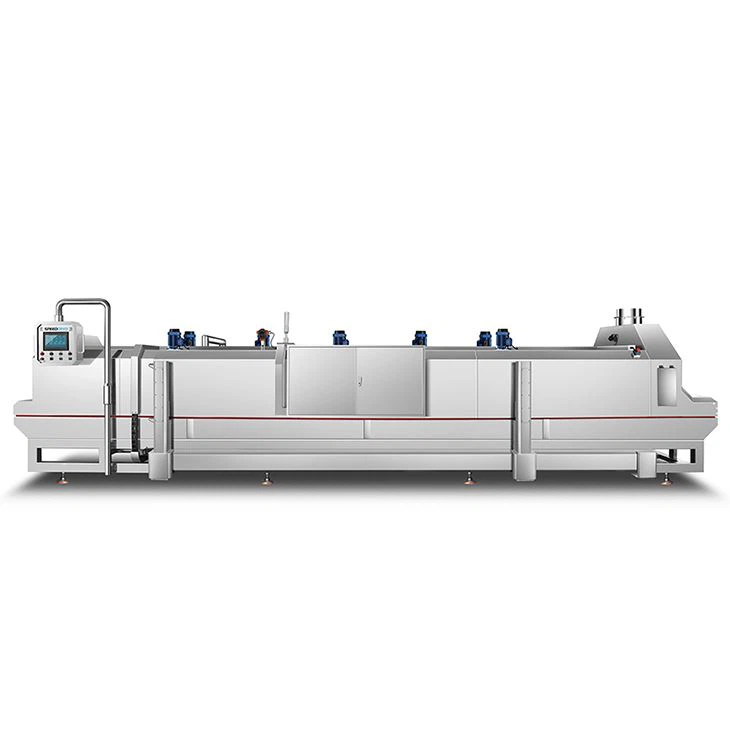

2. Product Parameter

| Model: | JSSD-0912 Liquid Nitrogen Iqf Freezer | ||

|---|---|---|---|

| Overall Dimensions: | 9140*2150*1900(mm) | Conveyor Dimensions: | 9000*1200(mm) |

| Inlet Length: | 960(mm) | Outlet Length: | 500(mm) |

| Inlet Height: | Adjustable 50 ~150mm | Freezing Capacity | 700 ~ 1000kgs/h |

| Weight: | About 4600 kgs | Voltage: | 380V |

| Material: | SUS 304 Stainless Steel | Power: | 11000W |

3. Product Features and Application:

For food processing enterprises with large processing volumes, especially for processing seafood, meat, poultry, prepared food, baked food, fruits, and vegetables, we highly recommend the liquid nitrogen iqf freezer for instant freezing, as it has extremely quick-freezing output and labor cost saving. Customized size of cryogenic iqf freezer could be used for existing production line or separate production line.

4. The Main Functions of the Operating System:

- Main Settings

- Advanced Settings

- System Alarms

- Temperature Curve

5. Product Qualifications:

- CE Certificates

- ISO 9001 Management System Certification

- Serving countless enterprises locally and abroad for 31 years

- More than 30 research experts

- More than 20 experienced engineer team

6. Customized Service

Guangzhou Speed Refrigeration Equipment Co Ltd is China well -known company in the cryogenic iqf freezer industry.

Liquid nitrogen iqf freezer is our main product. We provide food freezing development, engineering design includes size and length design, freezing capacity design, cryogen design, and electrical and pipe design.

When designing solutions for customers, fully consider the requirements of different kinds of food stuff, such as temperature, humidity, time, quality, package, control request, the food processing process specification, as well as a variety of design standards and safety requirements. We will try our best to provide energy-saving, environmental protection, and efficient food iqf freezers to customers.

7. FAQ:

What if the customer is not familiar with the product import process?

We have been engaged in liquid nitrogen iqf freezer export for more than 20 years, have rich experience in overseas shipments, and have long-term cooperative freight companies. We can provide EXW, FOB, CFR, CIF, DDU, DDP trade terms quotations according to customer requirements.

If the customer is not familiar with the import process, we generally recommend that the customer choose the DDP trade terms, we can arrange delivery to the door, and leave all operations to us after payment.