1. Product Introduction

Individual quick freezing machines, also known as cryogenic freezers, are revolutionary technology for frozen food processors seeking premium quality. Harnessing ultra-low liquid nitrogen temperatures, individual quick freezers rapidly freeze products down to the core while minimizing damage. This preserves original texture, moisture, and nutrition better than traditional methods.

Compared to slow-batch mechanical freezers, individual quick freezers using liquid nitrogen reduce freezing times from hours to minutes. The rapid freezing kinetics inhibit large extracellular ice crystals from forming, preventing the destruction of cellular structure. Quick freezing also limits chemical reactions that degrade flavor, pigments, and nutrients.

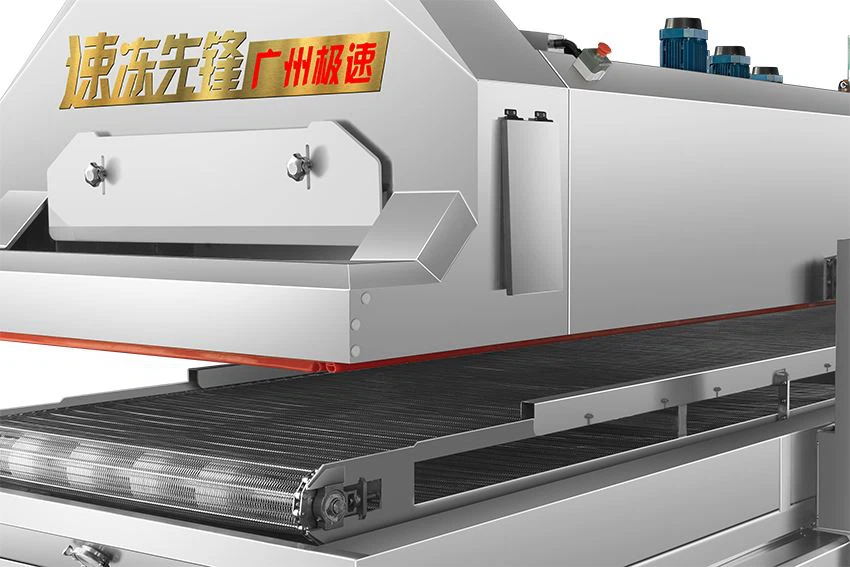

Individual quick-freezing machines employ tunnels with adjustable temperature profiles. Different zones can be set to optimize the freezing rate for the specific food item. Intelligent monitoring systems precisely control conveyor running time and product core temperature. This ensures sufficient exposure for full freezing without over-freezing.

Automated individual quick freezers simplify operations. The enclosed cryogenic process is safe for workers. Minimal labor is needed to load and unload products. Liquid nitrogen systems also take up less floor space than mechanical units.

2. Product Parameter

| Model: | JSSD-1112 Liquid Nitrogen Individual Quick Freezing Tunnel | ||

|---|---|---|---|

| Outer Size: | 11.06*2.15*1.90(m) | Belt Size: | 11*1.2(m) |

| Entrance Length: | 0.96(m) | Exit Length: | 0.5(m) |

| Inlet Height: | 50 ~150mm Adjustable | Freezing Capacity | 1000 ~ 1200kgs/h |

| Weight: | About 4900 kgs | Voltage: | 380V |

| Material: | SUS 304 Food Grade | Power: | 11 KW |

3. Product Features and Application:

- Length and width can be customized as per demands

- Minimum amount of floor space

- Low initial investment

- Liftable design, easy to clean and maintain

- 150mm thick thermal insulation layer

4. Details information:

- Friendly PLC Touch Screen Control System in Chinese and English Version

- 150mm Thickness Thermal Insulation Layer

- Oxygen Concentration Alarm System

- Precise temperature control and valve control to save liquid nitrogen

5. Product Qualifications:

- 103+Invention and Utility Patents

- CE Certificates

- ISO 9001 Certificates

- 20 Engineers with experience in research and development

6. Service

- One-year quality assurance (including the operating system, circulation system and fan).

- Paid equipment repair and maintenance lifetime service beyond the one-year quality guarantee

7. FAQ

Why do we choose individual quick freezing freezers instead of conventional freezers?

| Mechanical Freezers | Liquid Nitrogen Freezers | |

|---|---|---|

| Freezing Time | 120 – 300 Minutes | 5 – 60 Minutes |

| Cellular Structure Damage | 10-20% | 2-4% |

| Weight Loss | 5-6% | 1-2% |

| Appearance | Blackened and Dull | Maintain Best Appearance as Frozen before |

| Taste | Not Fresh and Water Loss | Maintain Fresh Taste as Frozen Before |

| Power Consume | 300~600KW (1 ton Food / Hour) | 18KW (1 ton Food / Hour) |

| Labor Cost | Required professional installation and maintenance. | No need for professional maintenance. |

| Low Efficiency, more cost for operation workers. | High Efficiency, less cost for operation workers. | |

| Floor Place | At least twice the floor place of the liquid nitrogen Freezer | Smaller Floor Place required and moveable |

| Environmental Pollution | yes - freon wreck the ozone layer | no |

| Safety Risks | yes - Ammonia explosive risks | no |

Cryogenic freezers involve lower upfront investment, the significant quality improvements quickly offset costs through higher yields, reduced waste, and premium pricing opportunities. Partner with our experts to integrate individual quick freezing into your production line. We can help you gain a competitive edge with high-end frozen products.